Two-Jaw Small Parallel Grippers

SPG Series

Lightweight Compact Grippers With Many Options

With its simple design, the SPG Series of parallel grippers is not only compact and lightweight, it also offers the widest range of customization options. This unique series features options for dowel pin precision mounting, adjustable stops, quiet high speed cycling, synchronization and much more.

The SPG Power Principle

The SPG Series features a specific design. With only three moving parts, these grippers are compact and lightweight.

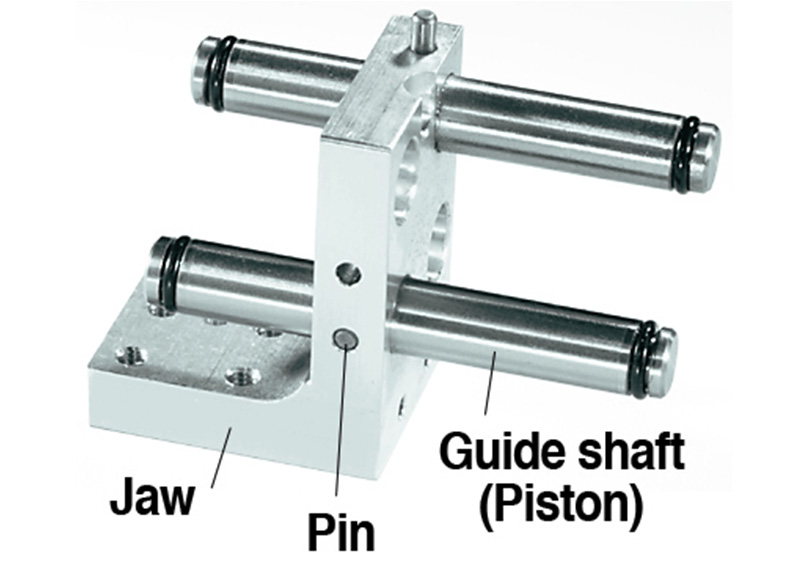

Jaw Construction

A pair of ground, stainless steel guide shafts double as air pistons and are press-fit and pinned to each gripper jaw. The shafts are placed diagonally and spaced far apart for maximum jaw stability.

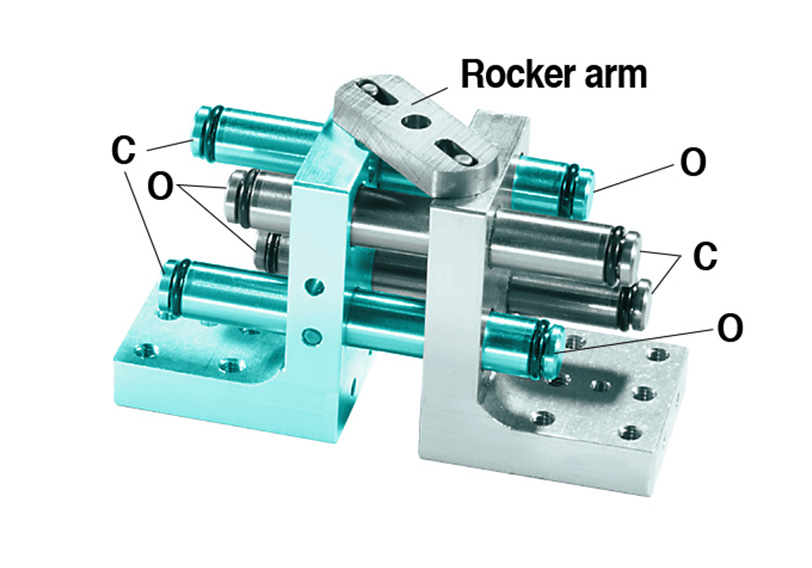

Three Moving Parts

The two jaw units link by the third moving part, a rocker arm, that synchronizes jaw motion. The arm does not drive the jaws, so wear is minimal.

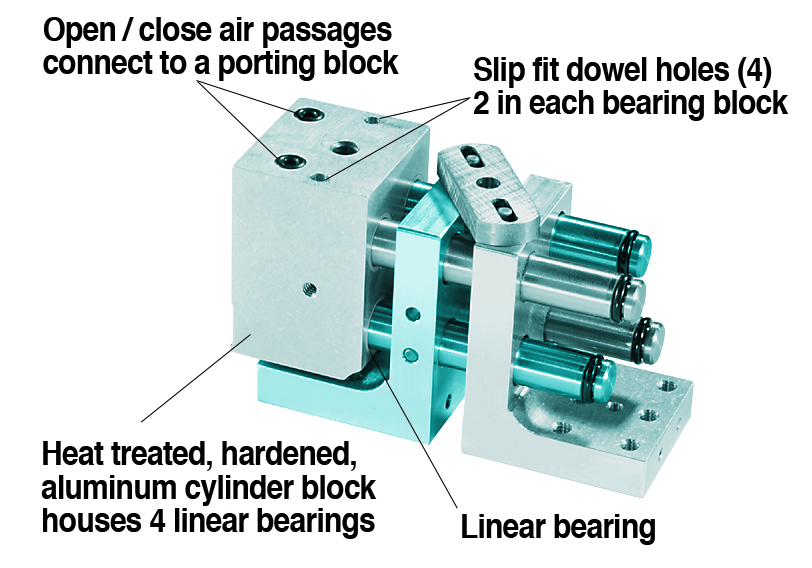

Symmetrical Cylinder Blocks

Four cylinders are bored in each of two blocks and connected by internal air passages to the "C" and "O" piston faces. These cylinders incorporate permanently lubricated, high-performance linear bearings that provide clean, drip-proof operation and allow the use of non-lubricated air supply.

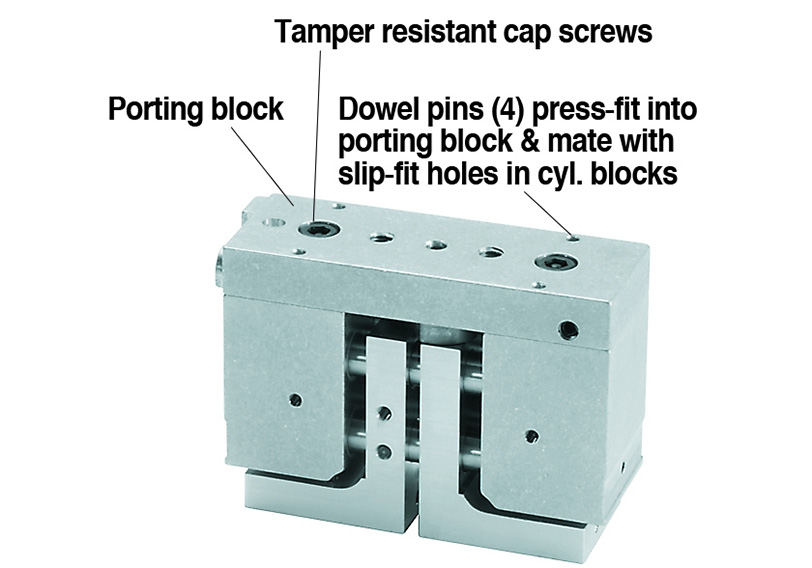

Porting Block Completes the Housing

With the SPG, there are no troublesome gibs to wear or adjust. Four dowel pins align the porting block perfectly with the cylinder blocks. Eight high-performance linear bearings guide the four pistons through the entire length of the gripper body. Centering accuracy maintains to 0.002 inch and side play is 0.0015 or less per jaw.

Key Specifications

Features

- Available in six stroke lengths: 0.25, 0.40, 0.54, 1.16, 1.38 and 3.75 inches

- Operating pressure standard at 100 psi

- Operating media: compressed air

- Repeatability: +/- 0.2 mm

Technical Advantages

- Only three moving parts

- Cylinder blocks symmetrical

- Porting block completes the housing

- Grip strength easily adjusted by varying pressure

- Lightweight and compact

Application Examples

- Heavy loads

- Part ejection

- Part handling

- Material transfer