Industries

Medical

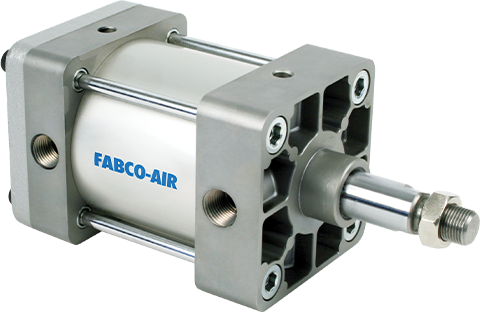

Quality Standard and Custom Cylinders For Clean Manufacturing

To meet the high reliability and cleanliness standards demanded by the medical industry, we offer both custom and off-the-shelf cylinders that help medical manufacturers keep their critical processes running smoothly.

For safe, reliable operation in medical and lab automation, Fabco-Air cylinders come in corrosion-resistant stainless steel and Delrin®, incorporate corrosion-resistant seals and use FDA-approved lubricants for use in many clean medical device or pharmaceutical production environments. Cylinders like our popular Pancake® series are also lightweight and compact—providing short strokes in a low-profile design and achieving the longest possible stroke for the smallest package size.

When it comes to medical device design and laboratory automation, we can also adapt our standard cylinders to meet your unique application needs. These specials can include many modified features related to size, media compatibility, temperature, material systems, sealing and more.

Technical Advantages

Key Benefits

- Corrosion-resistant seals and materials

- ISO 9001:2015 certification

- Compact, low-profile designs

- FDA-compliant materials

- Ability to customize standard products

- Complies with global standards—ISO 6431/32

Application Examples

- Clean manufacturing

- Glass vial production

- Medical device manufacturing

- Pharmaceutical production

- Lab automation

- Dental applications