NFPA Pneumatic Cylinders

NFPA and

OEM NFPA FCQN Series

Durable, NFPA-Interchangeable Cylinders With a Wide Range of Features

NFPA Series

NFPA pneumatic cylinders combine rugged construction and versatility. Available in a variety of versions and 17 mounting styles, these interchangeable NFPA cylinders allow users to directly replace other manufacturers’ NFPA units of the same type and dimensions for greater design freedom. The cylinder tube is built with a high-strength aluminum barrel, and users can also choose all-stainless steel, tandem, three-position and back-to-back models.

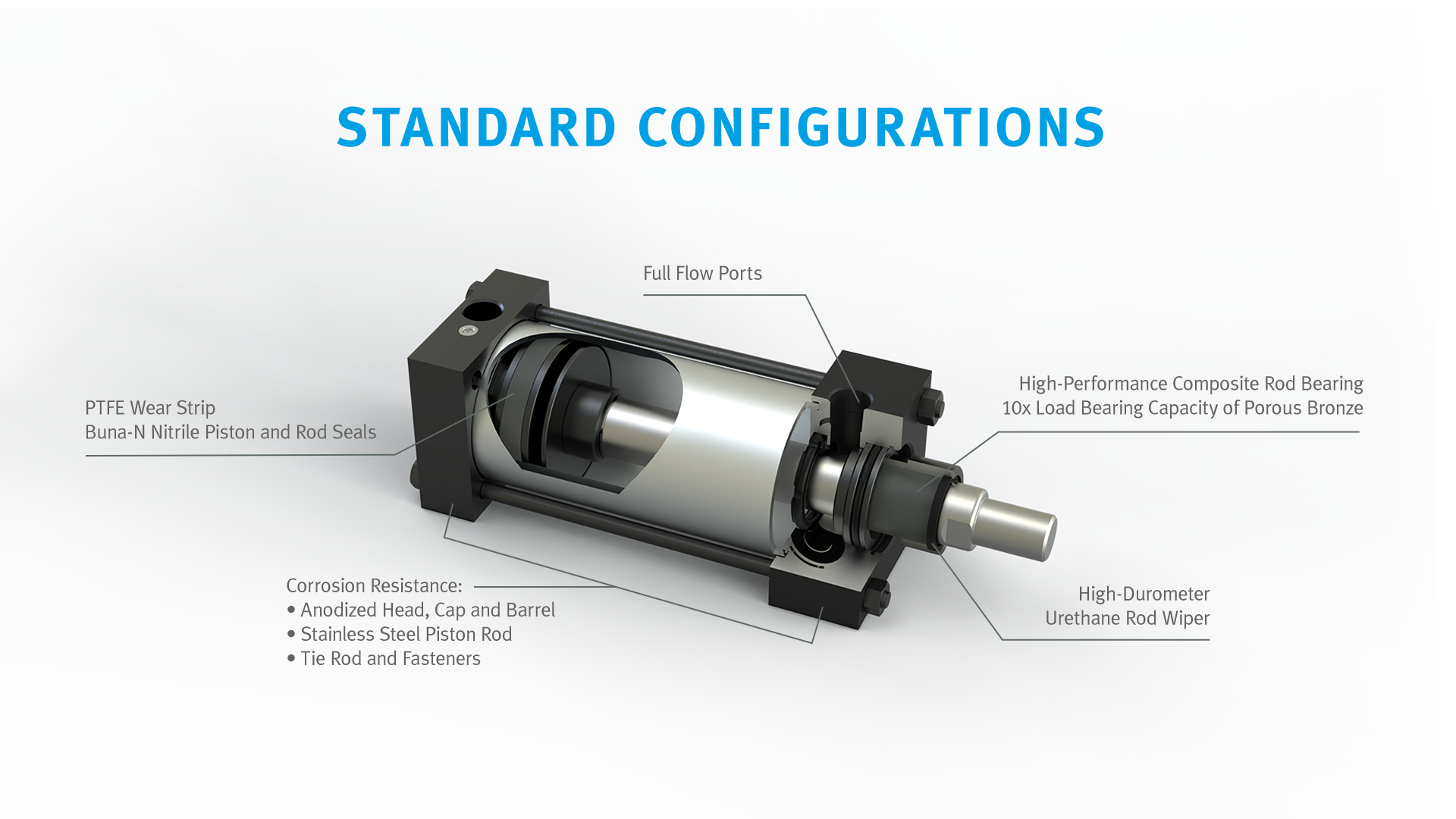

Featuring many rugged construction elements, these NFPA-standard cylinders deliver high performance and stand up to harsh environments. Their sturdy aluminum bodies have a 60-Rc inner diameter hard-anodized coating that actually impregnates the base material for added strength and surface protection. The steel tie rods are rated to 100,000 psi for maximum holding power, and an extra-long rod bearing made from a nonmetallic composite supports heavy loads while withstanding wear to ensure a long cycle life. A solid yet lightweight aluminum alloy piston includes a wide graphite-filled PTFE wear band to provide reliable performance under maximum load conditions. Each pneumatic NFPA cylinder comes pre-lubricated with Magnalube-G® grease for long life.

This series is rated to 250 psi max, offers a -10° to +165°F temperature range and is available with bore sizes up to 14 inches and standard strokes to 99 inches.

OEM-NFPA FCQN Series

FCQN Series OEM-NFPA pneumatic cylinders are ideal for designers requiring the convenience of an NFPA interchangeable, repairable unit. These OEM-priced cylinders come equipped with a full complement of features, making them a cost-effective option for a variety of applications with modest budgets. They’re also built strong, with hard-anodized aluminum bodies that resist corrosion and minimize internal friction, plus stainless steel tie rods and anodized end caps.

Each FCQN NFPA cylinder comes with magnetic pistons for position sensing and is outfitted with adjustable stainless steel air cushions on both ends. A special bushing provides long-life lubrication with Magnalube-G PTFE-impregnated grease. Thanks to its wide range of NFPA interchangeable mounting options, the FCQN pneumatic cylinder is also easy to install. Bore sizes range from 1 ½ to 4 inches, strokes are up to 48 inches and maximum operating air pressure is 140 psi.

Comparison

|

NFPA Series See NFPA Configurations | OEM-NFPA FCQN Series |

|---|---|

| Features | |

|

Bore sizes from 1 ½ to 8 inches, standard Bore sizes up to 14 inches upon request | Bore sizes from 1 ½ to 4 inches, standard |

| Standard strokes to 99 inches | Standard strokes to 48 inches |

| Pressure rating: 250 psi | Pressure rating: 140 psi |

| Temperature range: -10° to +165°F (-23° to +74°C) | Temperature range: -5° to +60°C (23° to +140°F) |

| Interchangeable per NFPA Standard Specification | Interchangeable per NFPA Standard Specification |

| Repairable design | Repairable design |

| Factory lube is Magnalube-G | Factory lube is Magnalube-G |

Construction features:

|

Construction features:

|

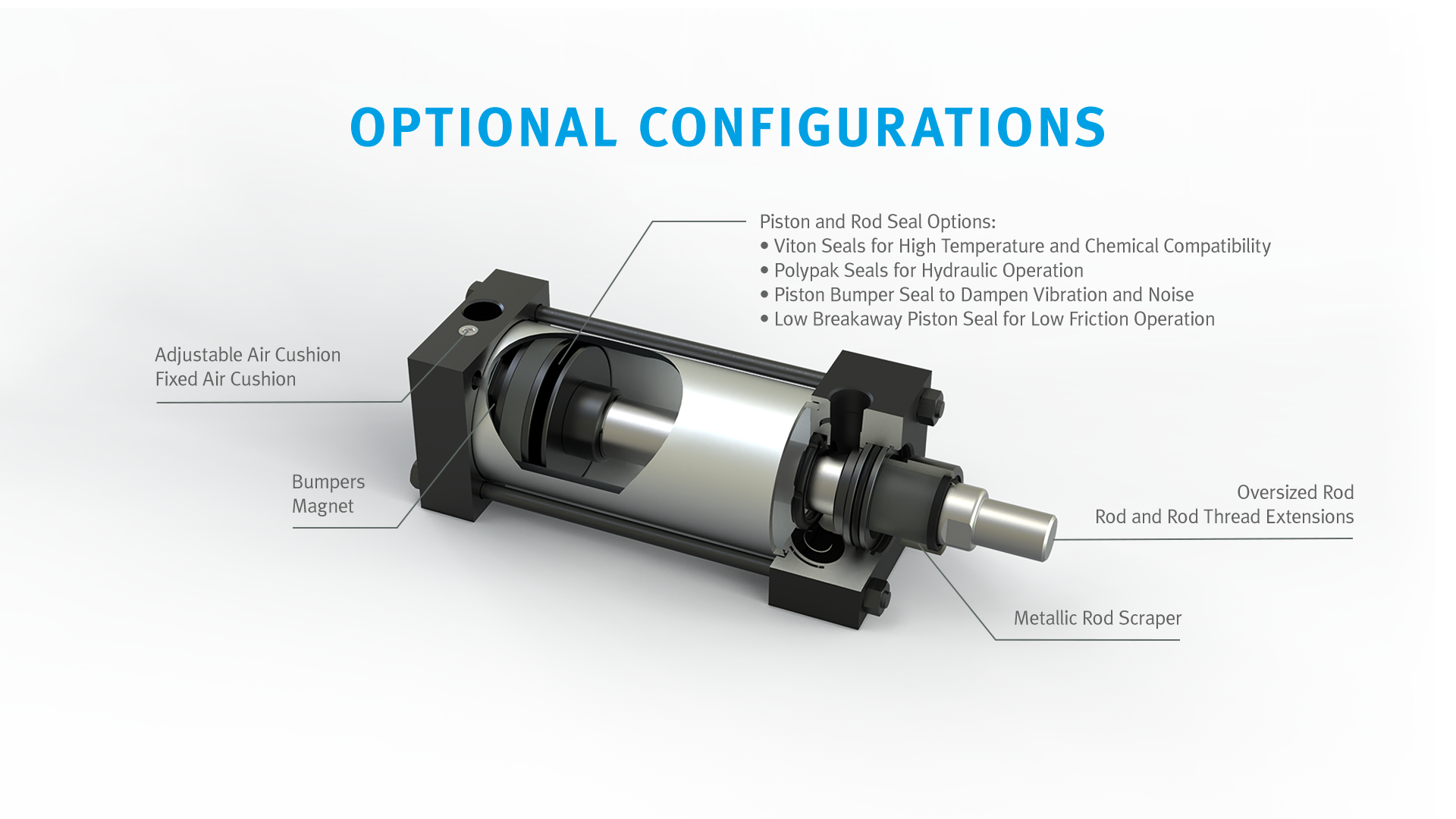

Additional options:

|

Additional options:

|

Special models:

| |

| Technical Advantages | |

|

|

Application Examples

- Conveyor belts

- Warehouse equipment