Tie Rod Cylinders

Hi-Power®

Maximum Stroke Efficiency for Applications With Space Constraints

When your design demands the most efficient use of space, Hi-Power cylinders are an ideal choice. Featuring tie rod construction, these double-acting, single rod cylinders are designed to provide the longest possible stroke versus their overall length. They also come in several mounting styles.

Additional features include a hard-anodized aluminum interior and exterior, hard chrome-plated stainless steel piston rods to ensure reliable operation and pre-lubrication with Magnalube-G® grease for long life. Hi-Power cylinders come in 10 bore sizes from 1 ⅛ to 12 inches and are available with strokes up to 12 inches. Air pressure is up to 250 psi, and maximum hydraulic service is 500 psi. The Hi-Power cylinder family is available in the following series:

HP Series Hi-Power Cylinders

The series is offered with ¼ inch stroke increments up to four inches.

THP Series Hi-Power Cylinders

Available with ¼ inch stroke increments through four inches and one inch increments from five through 12 inches, THP Series cylinders incorporate a PTFE piston bearing for effective load support and longer strokes.

UHP Series Hi-Power Cylinders

In addition to a PTFE piston for load support and long strokes, UHP Series cylinders include Buna-N U-cup seals for low break-away. They offer ¼ inch stroke increments through four inches and one inch increments from five through 12 inches.

Key Specifications

Features

- 10 bore sizes from 1 ⅛ to 12 inches and standard strokes to 12 inches (Consult factory for longer strokes)

- Composite rod bearing for longer life

- Prelubed with Magnalube-G grease

- Chrome-plated stainless steel piston rods

- Air service to 250 psi

- Hydraulic service to 500 psi

- Front face-rear face-foot-extended tie rod mounts

- Many options to choose from

- Magnetic piston sensing available

Technical Advantages

- Hi-Power cylinders are designed with a minimum overall length in relation to their strokes.

- Hard chrome-plated stainless steel piston rods ensure long cylinder life.

- The cylinder’s interior and exterior are constructed from hard-anodized aluminum to resist corrosion and exhibit low internal friction.

- Lightweight aluminum piston construction and secure piston assembly ensure precise concentricity for smooth cylinder operation.

- The piston rod-bushing is extra long and rigid. Its non-metallic high performance composite material ensures reliability and long life.

- High-performance composite resists corrosion, moisture and temperatures up to 325° F, while offering a high load capacity and very little friction.

- Buna-N O-rings are internally pre-lubed with Magnalube-G.

- Magnalube-G PTFE-impregnated grease provides a long operating life and lubricates across a wide temperature range.

- Several convenient mounting styles are available.

Application Examples

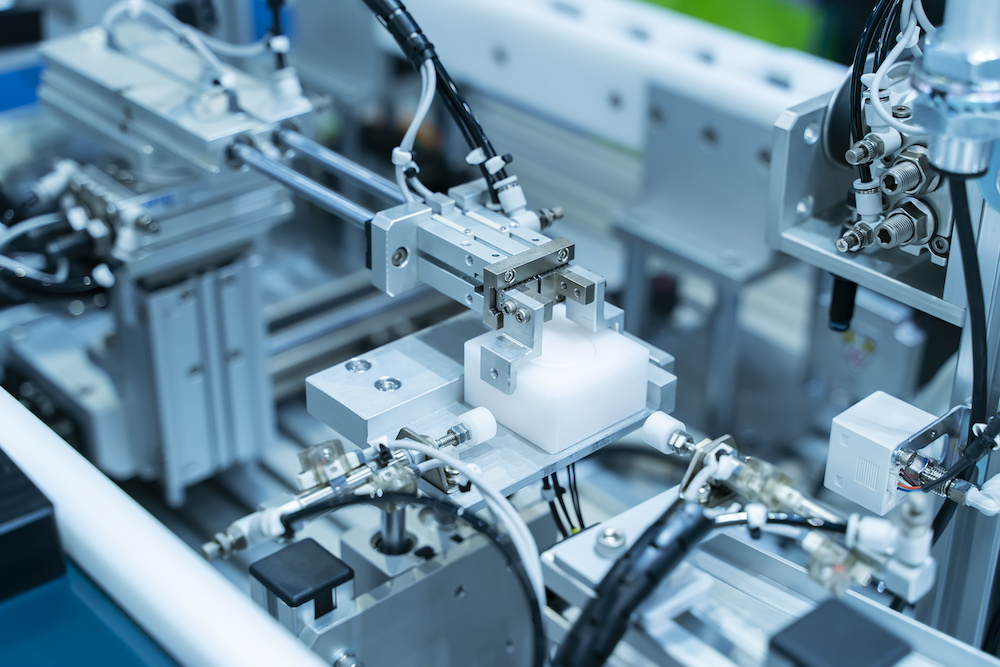

- Package sealing

- Wafer manufacturing

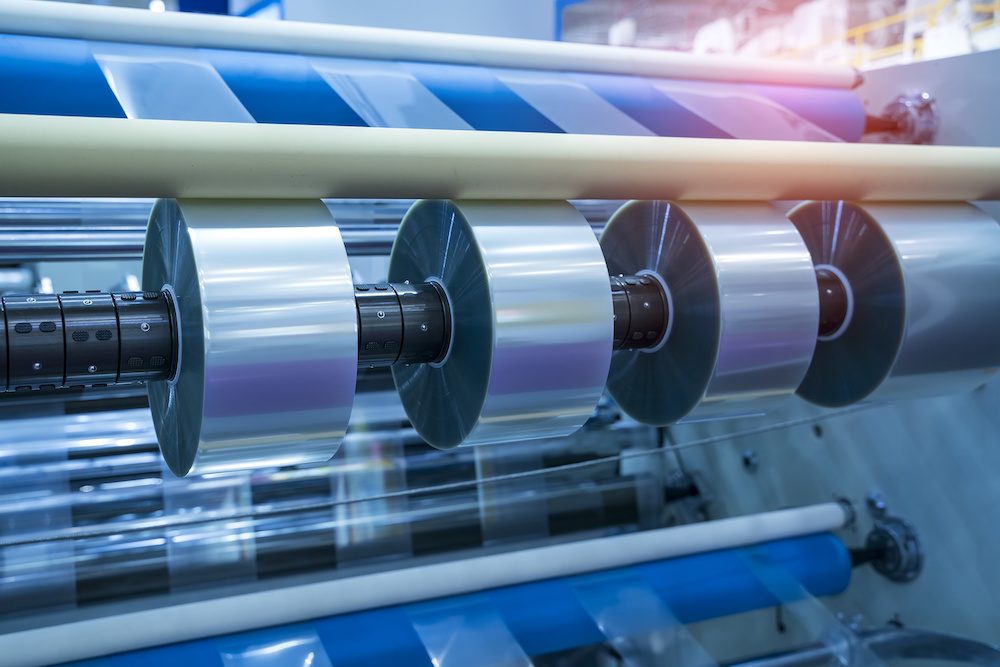

- Laminate slicing machines

- Punching, pressing and shearing

- Stamping